Our staff work strictly in accordance to the requirement of ISO/TS16949 to guarantee contimuous improvement of quality management system, quality, technology and cost, and:

1. To actively participate in all kinds of activities of quality management systems; follow out the quality policy in their work, strive for realizing the company's quality objective, and continuously improving the effectiveness of quality management systems, as well as product quality, process capability and process performance.

2. Focus on customers, satisfy customer requirements, improve customer satisfaction, and exceed the customer expectations.

3. Strictly implement the quality system documents to avoid occurrence of inconformity with the requirements of quality management systems.

4. Encourage and support staff spirit in innovation. In case of discovery of any improvement opportunities and other problems related with quality management systems, employees shall report timely to the organization by specific channel.

1) Quality Policy

We will continuously improve our product, service, and production process by:

1. Utilizing employee involvement;

2. Customizing the process to meet the needs and expectations of our customers;

3. Delivering to our customers on-time, defect-free products and services.

2) Quality Ensure Procedure

3)Product traceability

4)Inspection room

Inspection room keep the constant temperature and humidity / dust-free environment, using the import light from Germany. Inspector 100% check dimension, and according RR requirement to check the surface In the provision of the required lamp-house and light intensity. For the problematic products,100% use the measuring equipment to check and decision that the defect meet the requirement or not, and submit the related repot to customer.

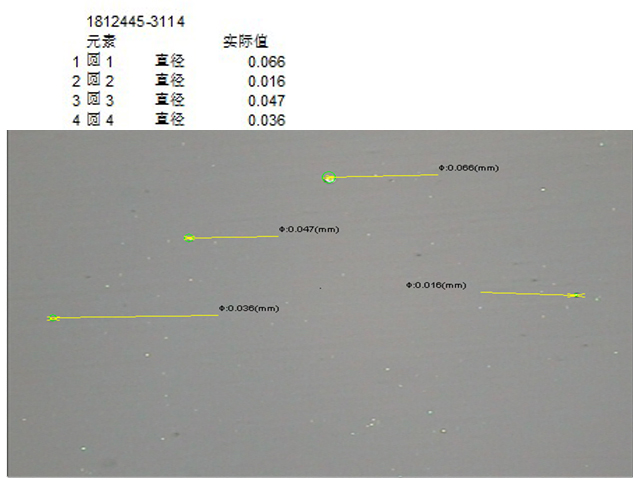

5-1) Test Facility—Projector

1. According inspection standard to check the in-process parts.

2. According plan to do the products review every month.

3. Confirm the problematic products.

5-2)Test Facility—CMM

1. According inspection standard to check the in-process parts.

2. According plan to do the products review every month.

3. Confirm the problematic products.

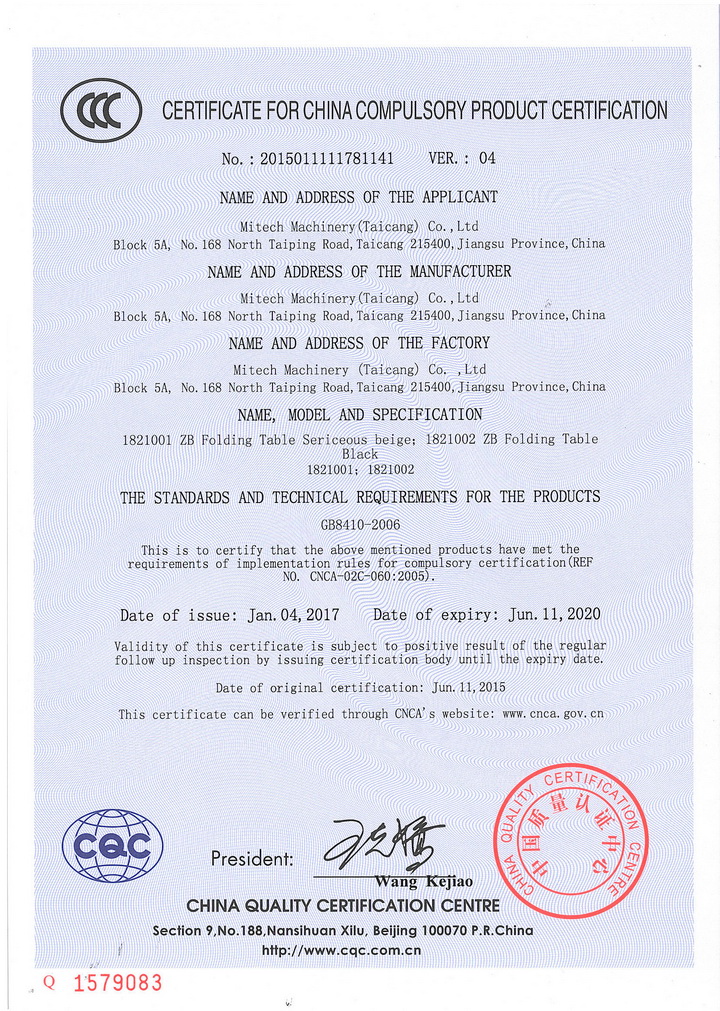

6) Certificate

|